Every one in the metro cities like Kolkata, Delhi enjoying the luxuries of the metro train ever spared a thought about the train? No, then let me give you a brief idea about the driverless automatic driven and controlled train. But before that let us have a brief recall about types of metro automation.

The Driver Controlled Mode:

In conventional modes, it’s the manual driver who drives the train and controls the train motion using the stationary light signals.

The Partially Automatic Mode:

In this mode, the driver drives the train while an external control system is used to constantly monitor the speed and acceleration of the train and provide required feedback to the driver.

Driverless Mode:

The whole operation and maintenance of the train is done automatically without any human intervention. The train stops and starts automatically and the doors are closed and opened automatically.

So, now let us fix our attention to the last mode i.e. The Driverless Mode

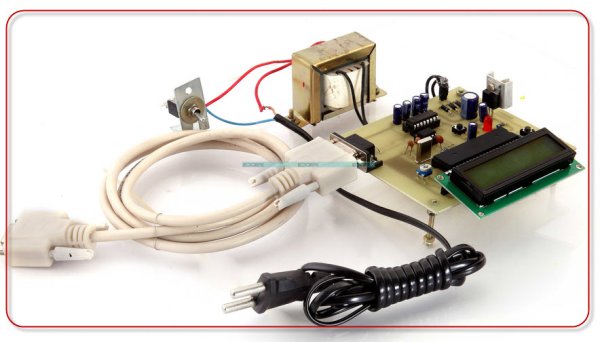

In a fully automatic driverless train, the control is done through a Communication based train control where a trackside computer is used to monitor the train running on the assigned line and convey this information to the centralized computer. The train is controlled by the automatic train control system.

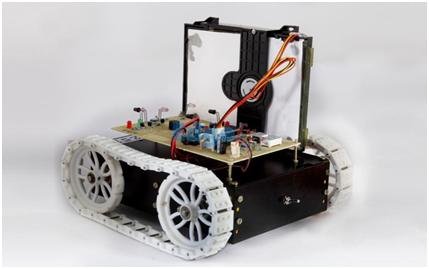

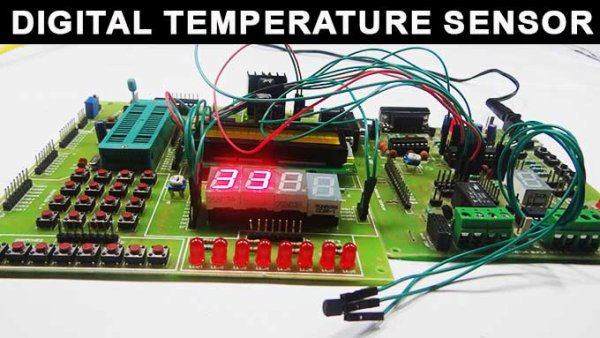

Designing a Basic Prototype of a Automatic Driverless Train

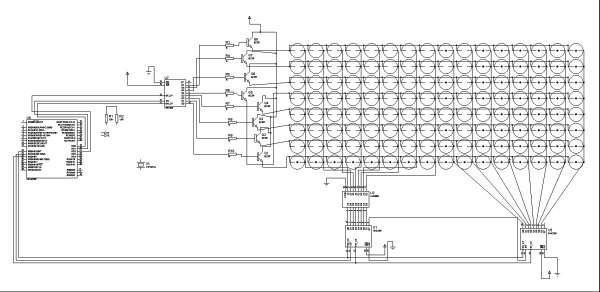

The design will include the following components:

- A rectangular body which holds all the other robotic components like the control circuit, the door etc.

- A sliding door prototype

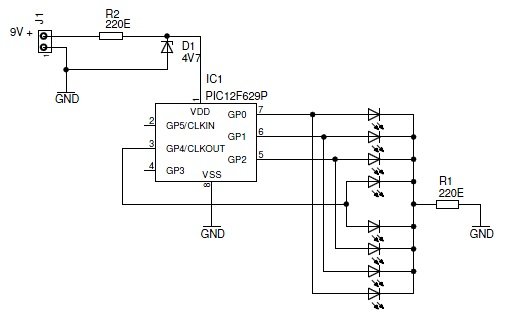

- A couple of IR LED and photodiode arrangement

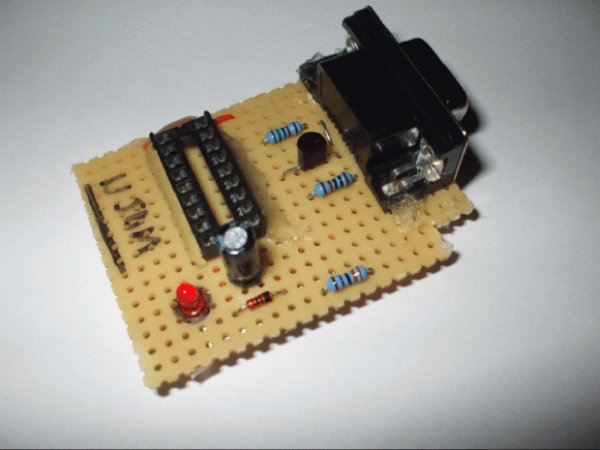

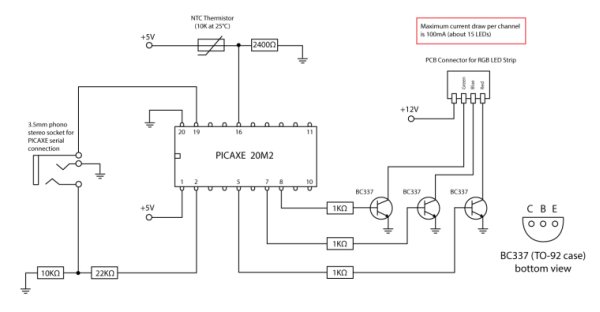

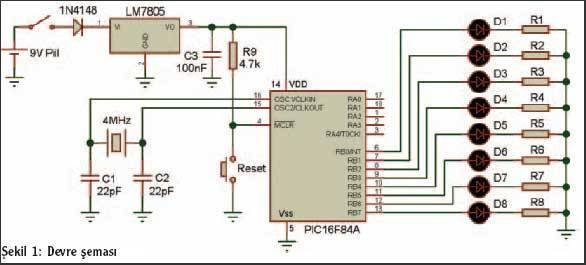

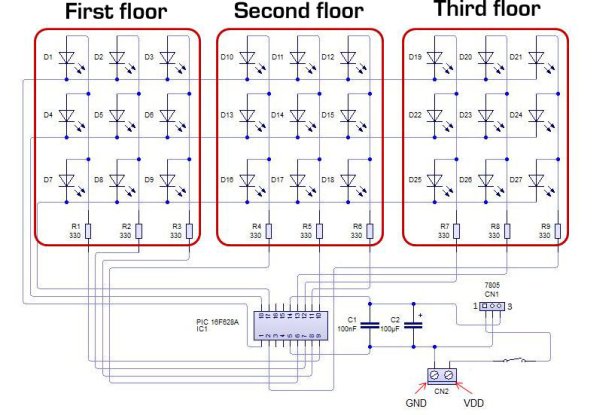

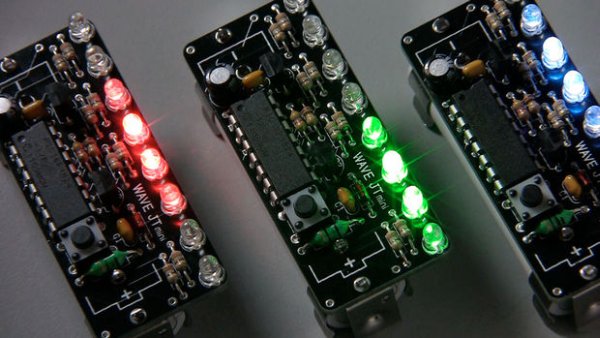

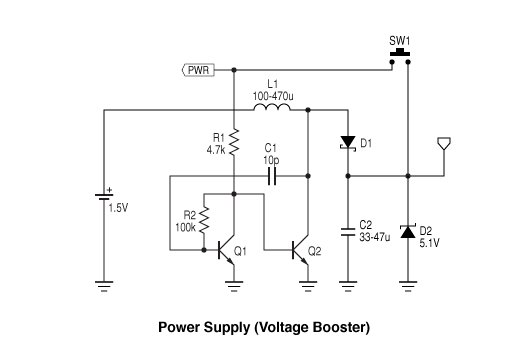

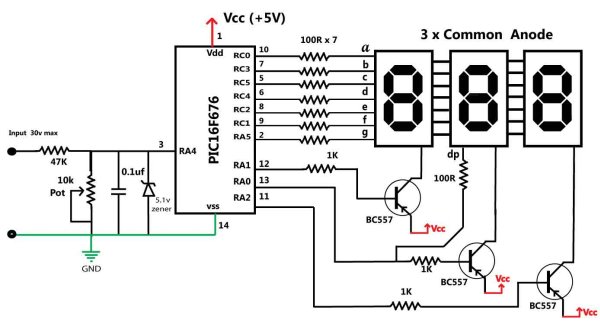

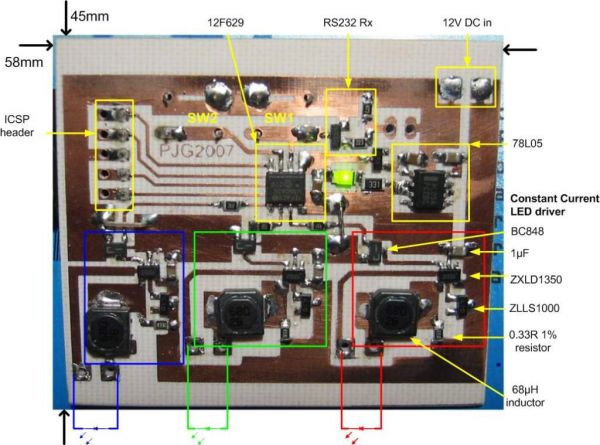

- A control circuitry using a Microcontroller

Working of the Basic Prototype:

So let us see how our basic prototype works does:

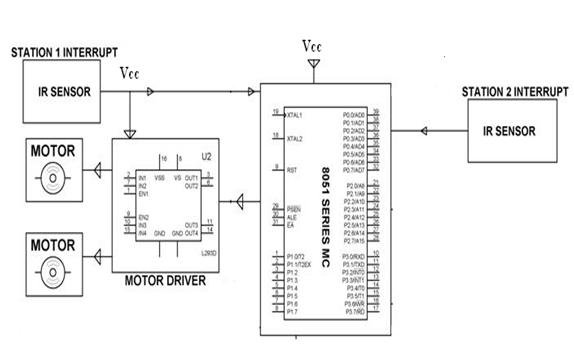

- The Automatic platform sensing and Door control system: It consists of an IR LED and a photodiode system. When the sensor senses the coming of the station, the motor driver automatically drives the motor such that the train comes to a halt and the door is opened when a person is sensed.

- Passenger counter system: The train is also equipped with a passenger counter system which counts the number of passengers entering the train and when the count reaches a certain limit the door is closed automatically and the train will start moving after a certain time limit.

How to controls the Train Prototype:

- Controlling the movement of the train: Normally when the train is moving, the IR LED-photodiode arrangement is placed such that both are placed parallel to each other and thus as the photodiode doesn’t gets the light pulses, it doesn’t conducts and as a result the microcontroller will get a high signal. Now as the train approaches a station, the IR light from the IR LED gets reflected by any object (suppose the station signal) and the reflected light falls on the photodiode, causing it to conduct and thus an interrupt low signal is given to the microcontroller through the transistor. The microcontroller is programmed so as to send signals to the motor driver to stop the motors. The operation of the motor is driven by the motor drive IC; here two stations are connected to the microcontroller through the motor drive.

For more detail: Easy Way to Design an Automatic Driverless Train

The post Easy Way to Design an Automatic Driverless Train appeared first on PIC Microcontroller.